A leading precision component manufacturer.

Explore CapabilitiesQdFuxingtong bridges the gap between raw material supply and advanced manufacturing, offering a single-source

solution for the aerospace and energy sectors. By integrating state-of-the-art precision casting, forging,

and additive capabilities with a rigorous quality assurance framework, we deliver critical components that

meet the most demanding performance standards. From certified raw alloys to finished, flight-ready hardware,

we ensure uncompromised quality and reliability at every step of the supply chain.

Manufacturing critical engine hardware, including precision-cast turbine

blades, structural housings, and fully integrated fuel systems for next-generation aerospace

applications. Delivering heavy-duty solutions for the energy sector, from large forged

rotors and IGT vanes to wear-resistant components for power generation systems. Providing a comprehensive inventory of high-performance raw materials,

certified metal powders, welding consumables, and standard aerospace hardware. We tailor our manufacturing processes to fit your unique business

needs, offering a full spectrum of design and logistical support. Whether you provide detailed technical drawings, physical samples, or specific on-demand

requirements, our engineering team can translate your vision into reality. We offer streamlined support for adding your visual identity to products, including custom

logos, specialized packaging, and bespoke graphics. Simplify your supply chain with our cross-category consolidation services. We bundle multiple

product types into single shipments to maximize delivery efficiency and reduce logistics

costs. Our production scales seamlessly from small trial runs to mass manufacturing. Our commitment to quality is absolute, supported by advanced

equipment and strict protocols at every stage of production. Quality begins at the source. All incoming raw materials undergo strict inspection procedures

and are tagged with traceability labels to ensure complete accountability. Our facility is equipped with professional-grade testing equipment, allowing us to validate

material strength and product performance against industrial standards. We refuse to compromise on consistency. Every single finished unit undergoes a comprehensive

quality inspection before it leaves our facility. We maintain a complete quality trail, supporting full traceability from raw material sourcing

to the final delivery, giving you total peace of mind. Delivering exceptional structural integrity through closed-die forging

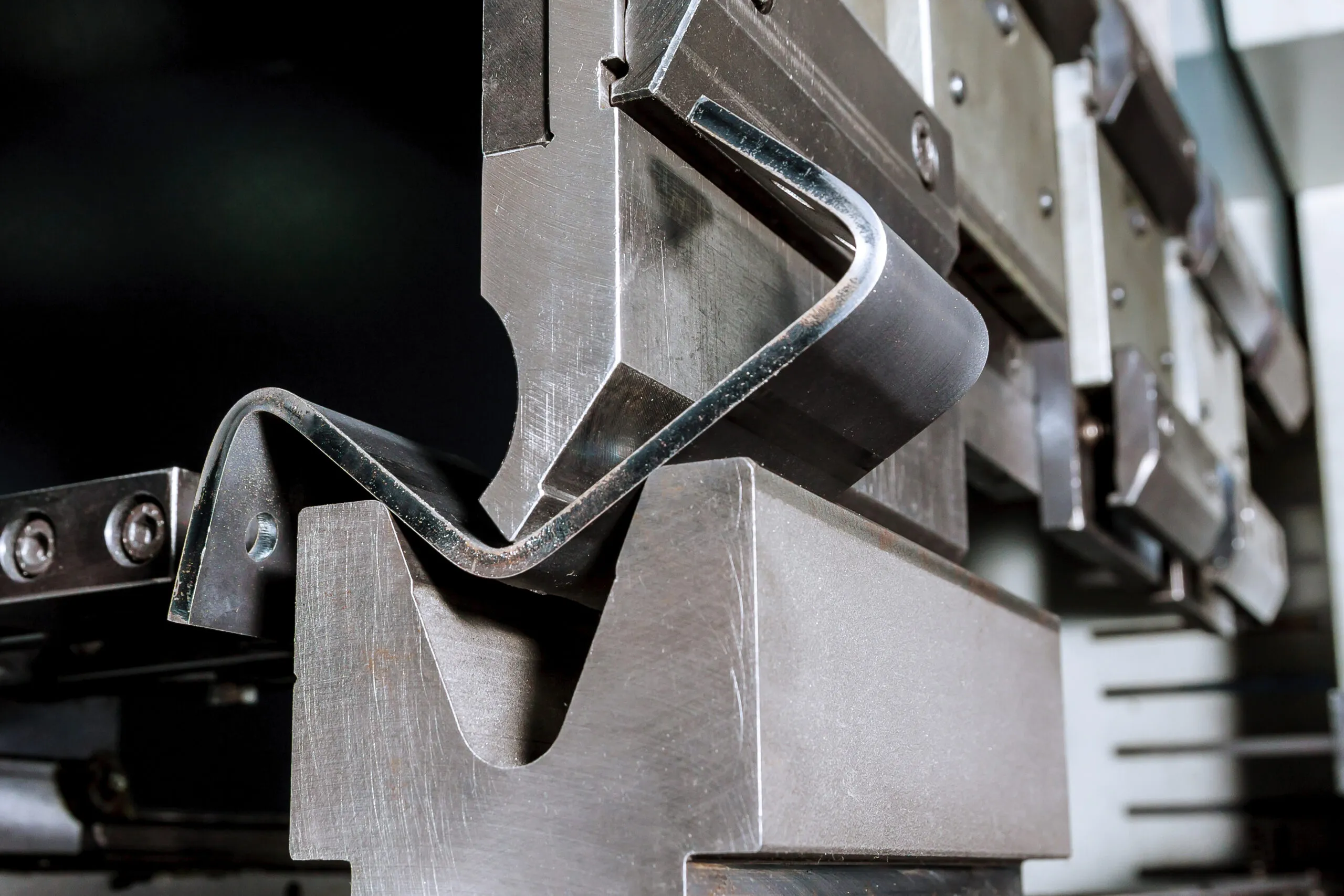

and ring rolling of high-strength superalloys for critical rotating parts. Shaping intricate, thin-walled aerospace components using

state-of-the-art hydroforming, superplastic forming, and precision tube bending technologies.

Producing complex, high-performance components via advanced vacuum

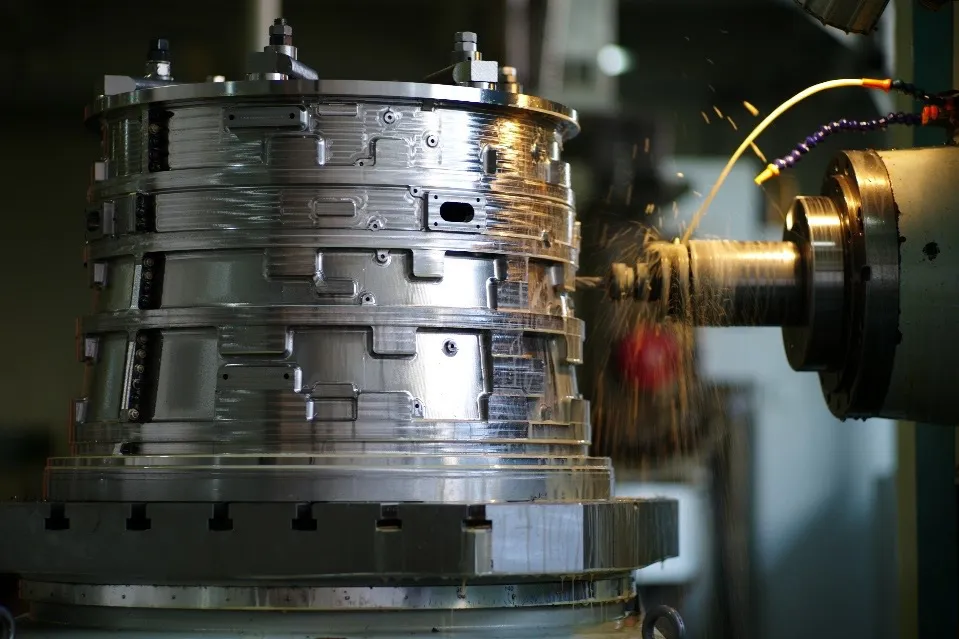

casting (Equiaxed, DS, SX) and powder metallurgy for superior dimensional accuracy. Achieving tight tolerances on difficult-to-machine alloys using 5-axis

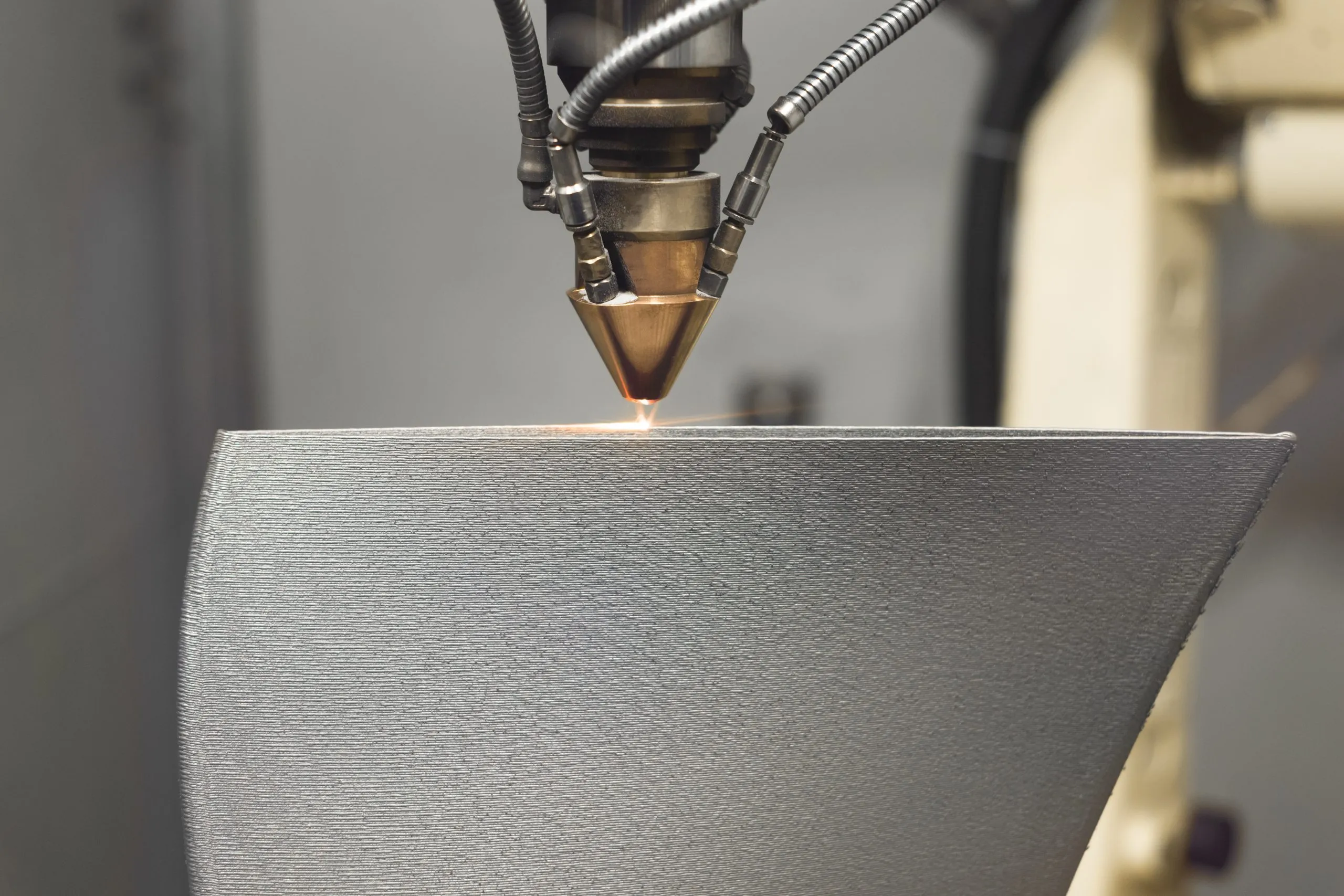

CNC milling, turning, and advanced EDM/ECM finishing processes. Enabling rapid prototyping and complex geometry production with

next-generation metal 3D printing methods (PBF, LMD, WAAM).Business Scope

Aviation

Oil & Gas

Material Supply

Our Advantages

Flexible Customization & Service

Versatile Design Adaptation

Brand Personalization (Light Customization)

Strategic Product Consolidation

Scalable Manufacturing

Rigorous Quality Assurance

Verified Raw Materials

Professional Testing Infrastructure

100% Finished Product Inspection

End-to-End Traceability

Production Capabilities

Forging

Forming

Casting

Machining

Additive Manufacturing

Special Processes

Explore →

Proudly Working With