Our Forging Division provides advanced manufacturing solutions for high-performance components used in aerospace engines, industrial gas turbines, and energy-generation systems. Combining state-of-the-art forging equipment, precise process control, and optimized heat-treatment systems, we produce components with superior mechanical properties, structural integrity, and dimensional accuracy.

Our infrastructure enables the production of a wide range of forged and ring-rolled components, consistently delivering superior metallurgical quality and mechanical performance. Our operations include:

.webp)

Disk

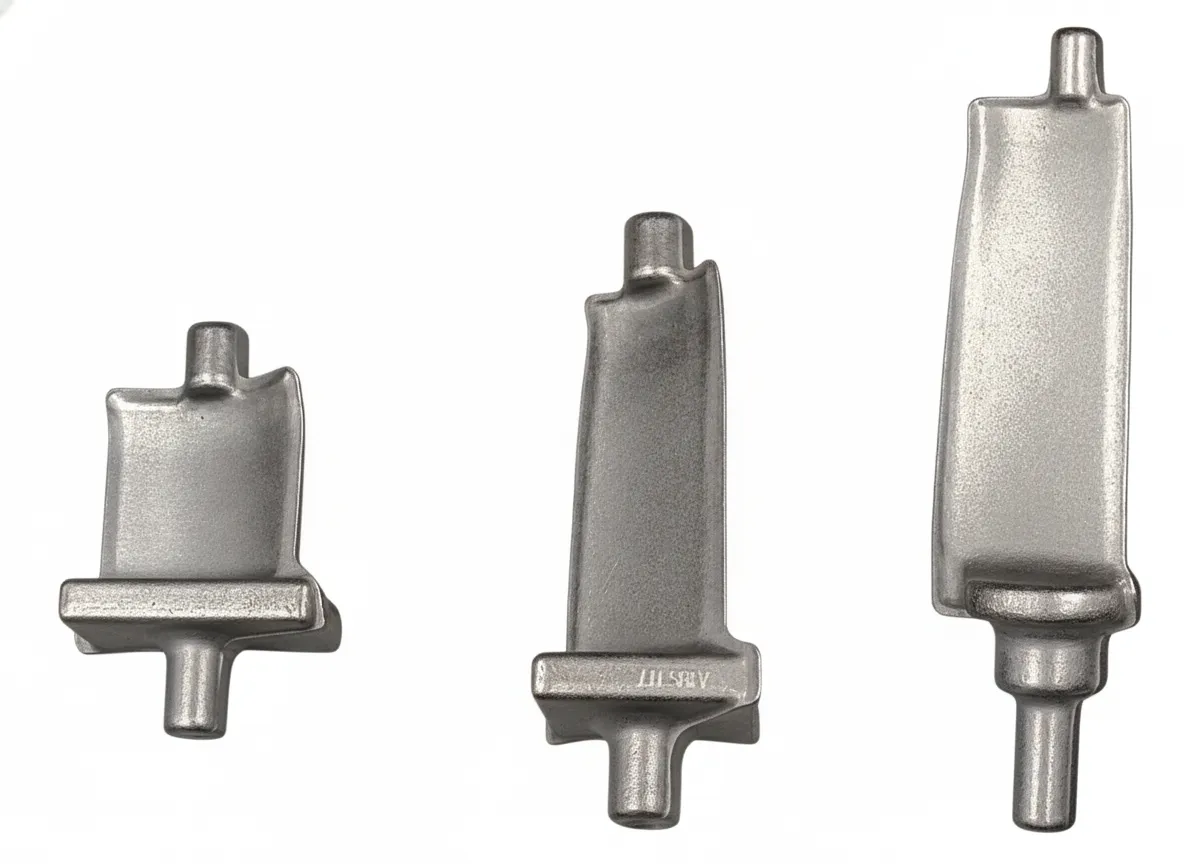

Blade

Shaft

Vanes

Casing

Supporting Ring