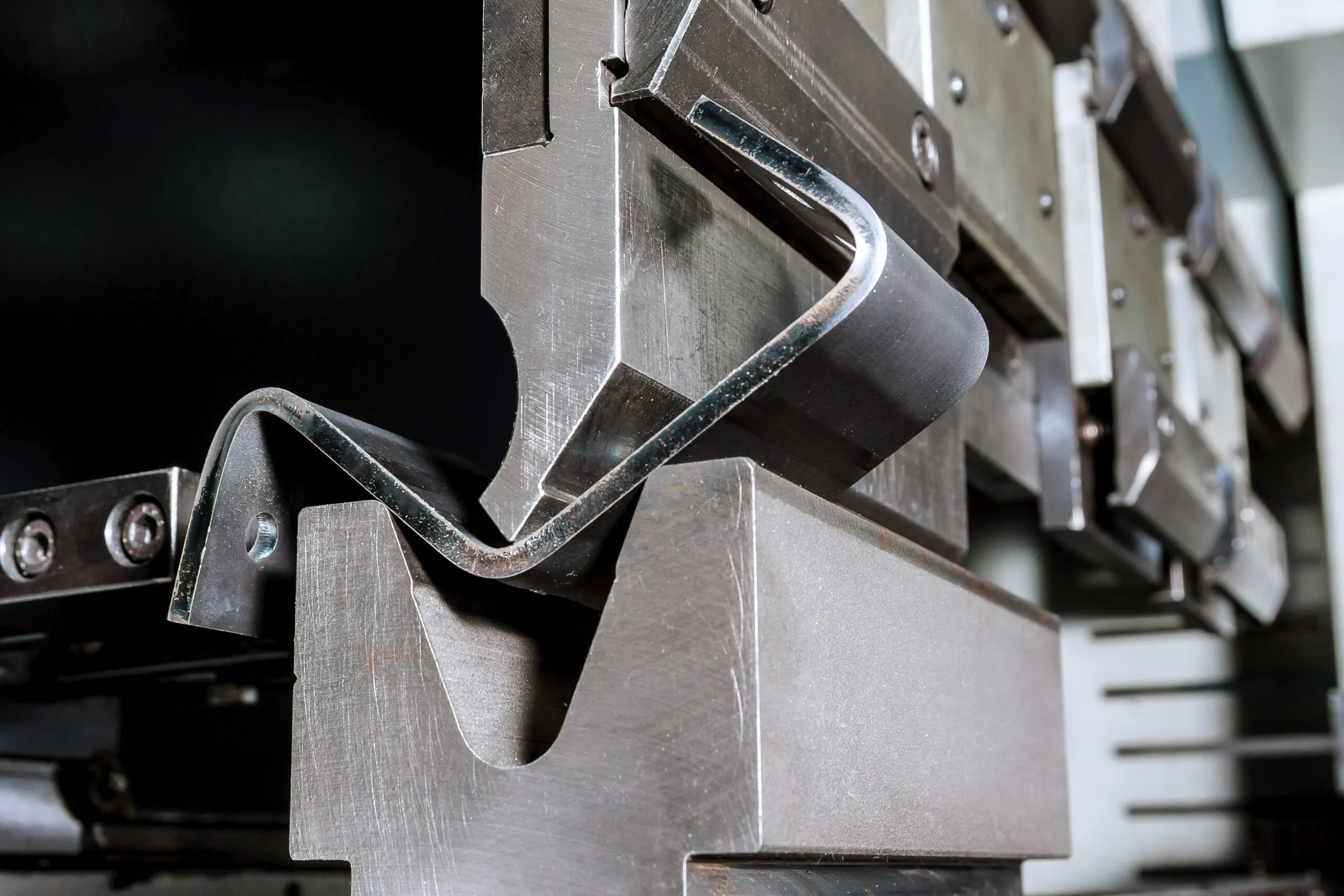

Our Forming Division provides advanced solutions for shaping high-performance components used in aerospace engines, industrial gas turbines, and other demanding applications. Utilizing state-of-the-art forming technologies and precise process control, we produce components with complex geometries, excellent dimensional accuracy, and superior mechanical properties.

Our forming operations allow production of components with intricate shapes, thin walls, and tight tolerances, meeting the demanding requirements of aerospace and industrial applications.

Fuel Pipe

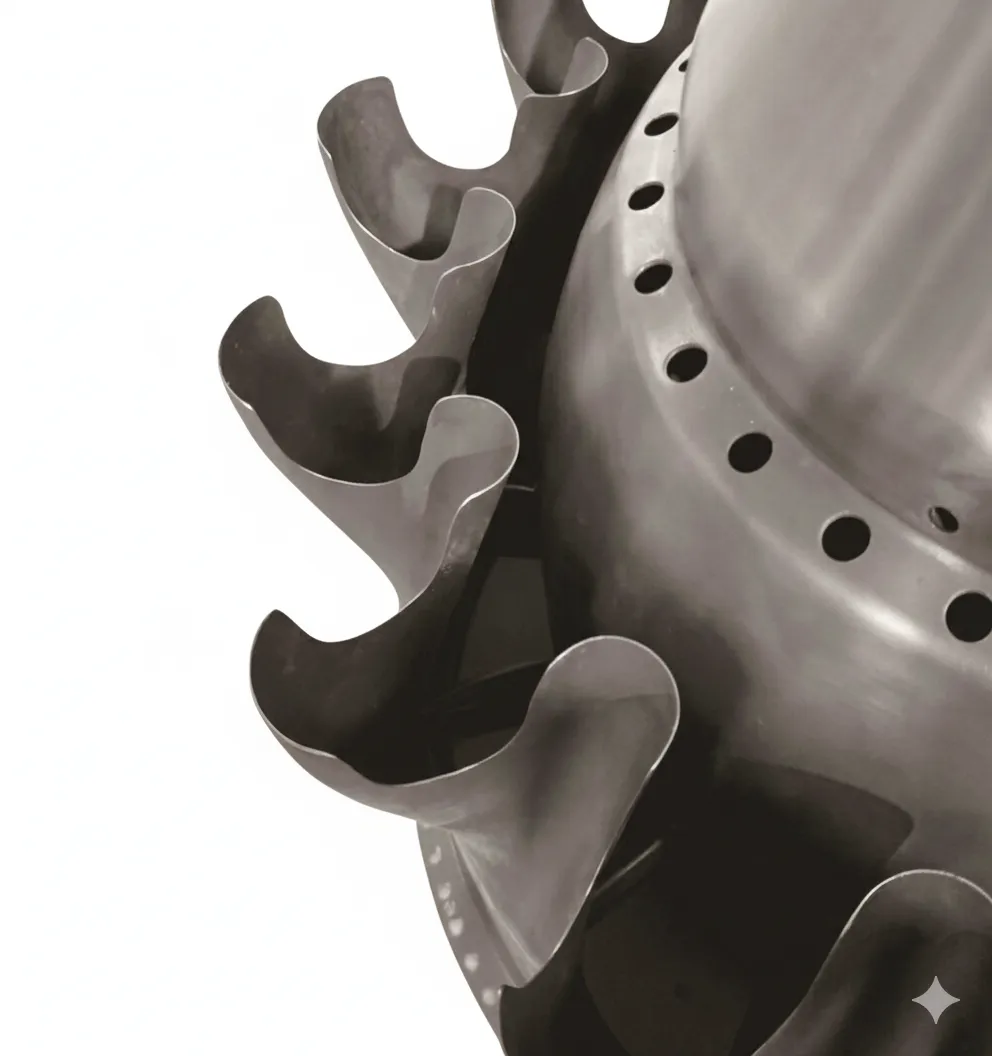

Combustion Chamber

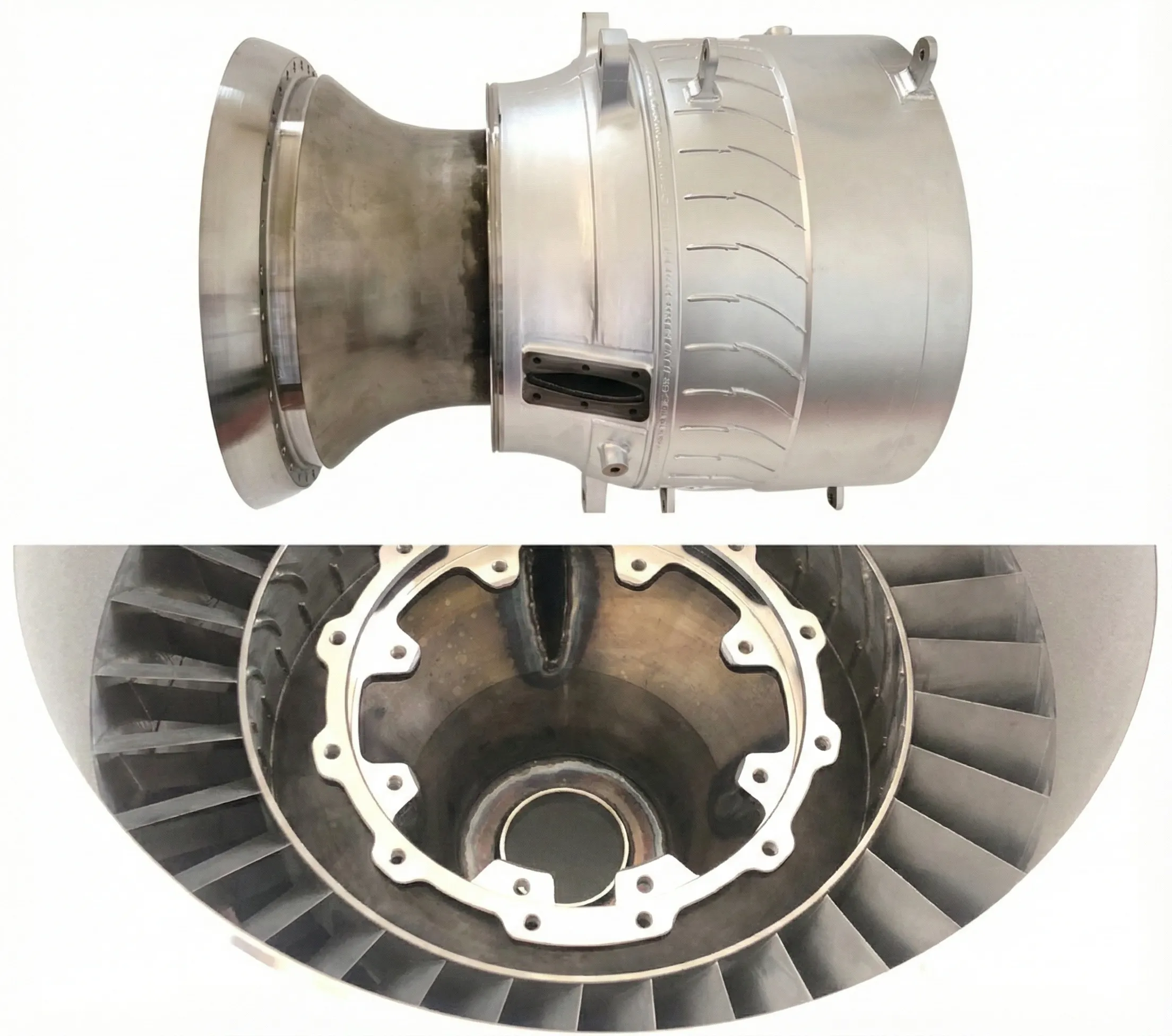

Engine Casing

Casing

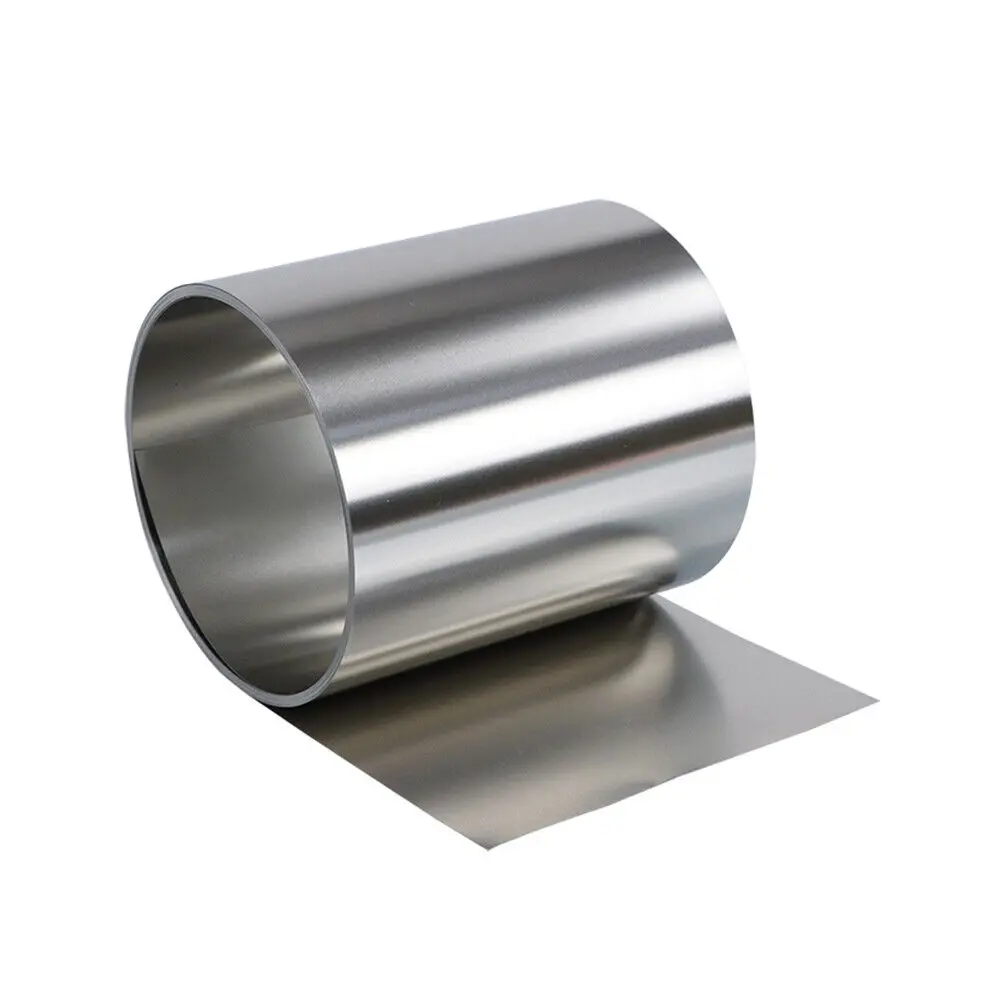

Sheet Metal

Combustion Chamber